🌬️ Project 1: HVAC Control System with PID, Damper & Alarm Handling

This project simulates a real-world HVAC control system using Rockwell Studio 5000 and FactoryTalk View SE HMI. It features Auto/Manual mode handling, PID-based damper regulation, reusable AOI/UDT structures, and a full alarm/notification system.

🧠 System Overview

- Auto & Manual operating modes with interlocks

- PID loop for temperature control (damper modulation 0–100%)

- Supply and Return fans controlled via AOI_FanControl

- Deviation-based damper fault detection (>10% for 5s)

- Alarm latching with buzzer & reset

- Modular routines:

IO_MAP,MODE_HANDLING,TEMP_PID,DAMPER_CONTROL,FAN_CONTROL,FAULT_MONITOR,ALARM_HANDLER - HMI navigation: Home, Fan, Damper, PID, Alarm

📄 Project Reports

1. Final Report

Full design report covering objectives, hardware/software setup, logic flow, tag lists, UDTs, AOIs, and test procedure.

2. Ladder Logic with Rung Comments

Documented ladder routines with rung-by-rung comments for IO, Mode, PID, Fan, Damper, Faults, and Alarms.

🖼️ HMI Screens (FactoryTalk View SE)

Home / Navigation

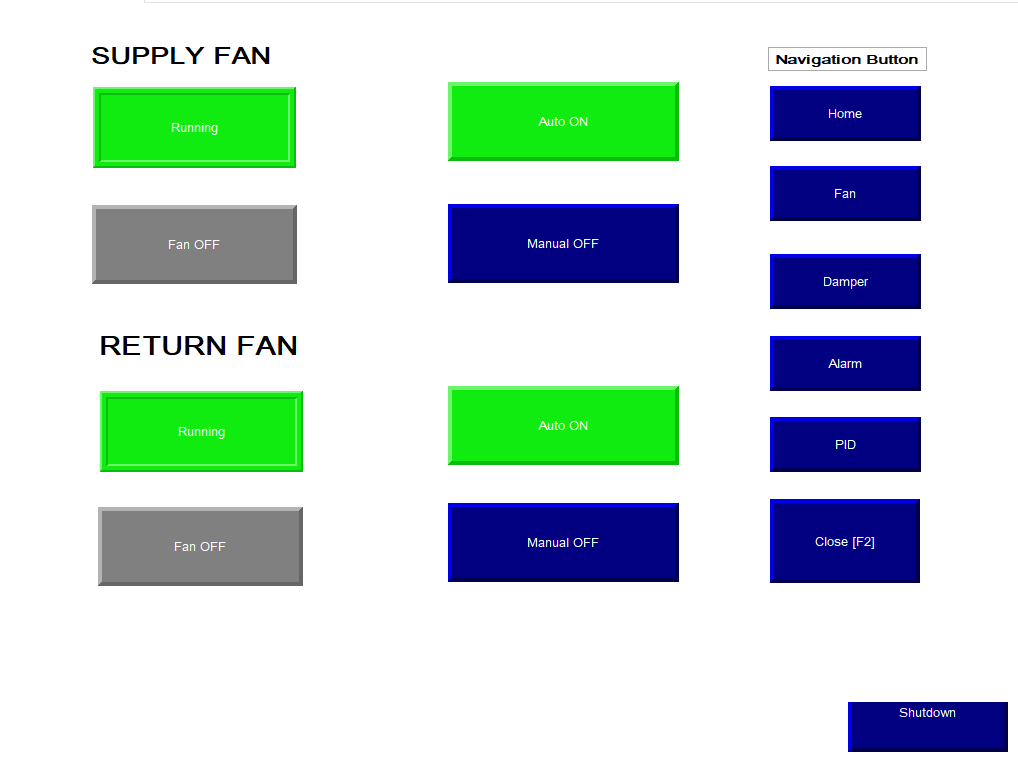

Fan Control Screen

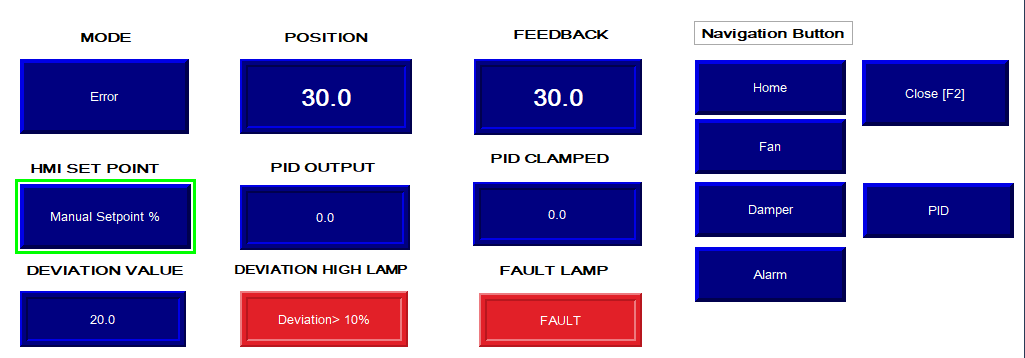

Damper Control Screen

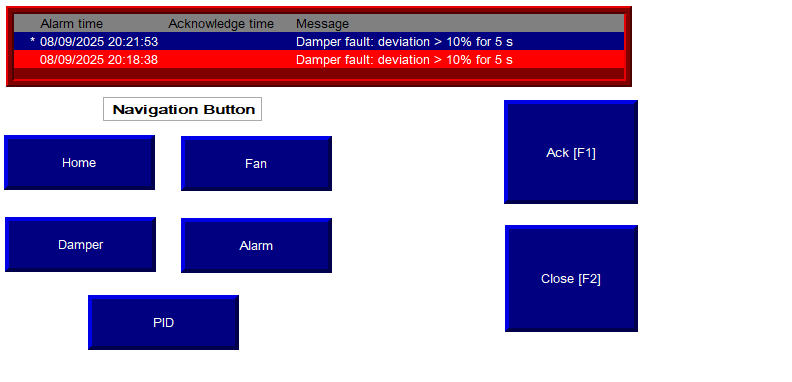

Alarm Banner & Acknowledgment

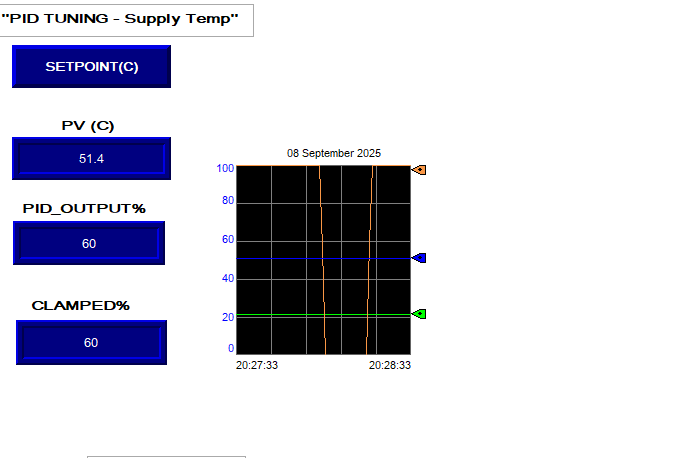

PID Tuning & Trending

These screens demonstrate:

- Auto/Manual selection and mode lamps

- Fan status, start/stop, and feedback

- Damper command vs feedback + deviation alarms

- PID tuning interface with PV/SP/output trending

- Alarm banner with Ack/Reset

🧪 Testing & Results

- Fans start automatically in Auto mode

- Manual mode allows direct fan & damper control via HMI

- PID loop regulates damper position to maintain setpoint

- Damper fault alarm triggers correctly (>10% deviation for 5s)

- E-Stop immediately latches system fault

- Alarm buzzer & reset tested successfully